The Aurora Borealis Curtain Wall is a project made using over 3,000 cylinders hand fabricated using reclaimed paint chips & fabric samples from design studios & vendors across the bay area.

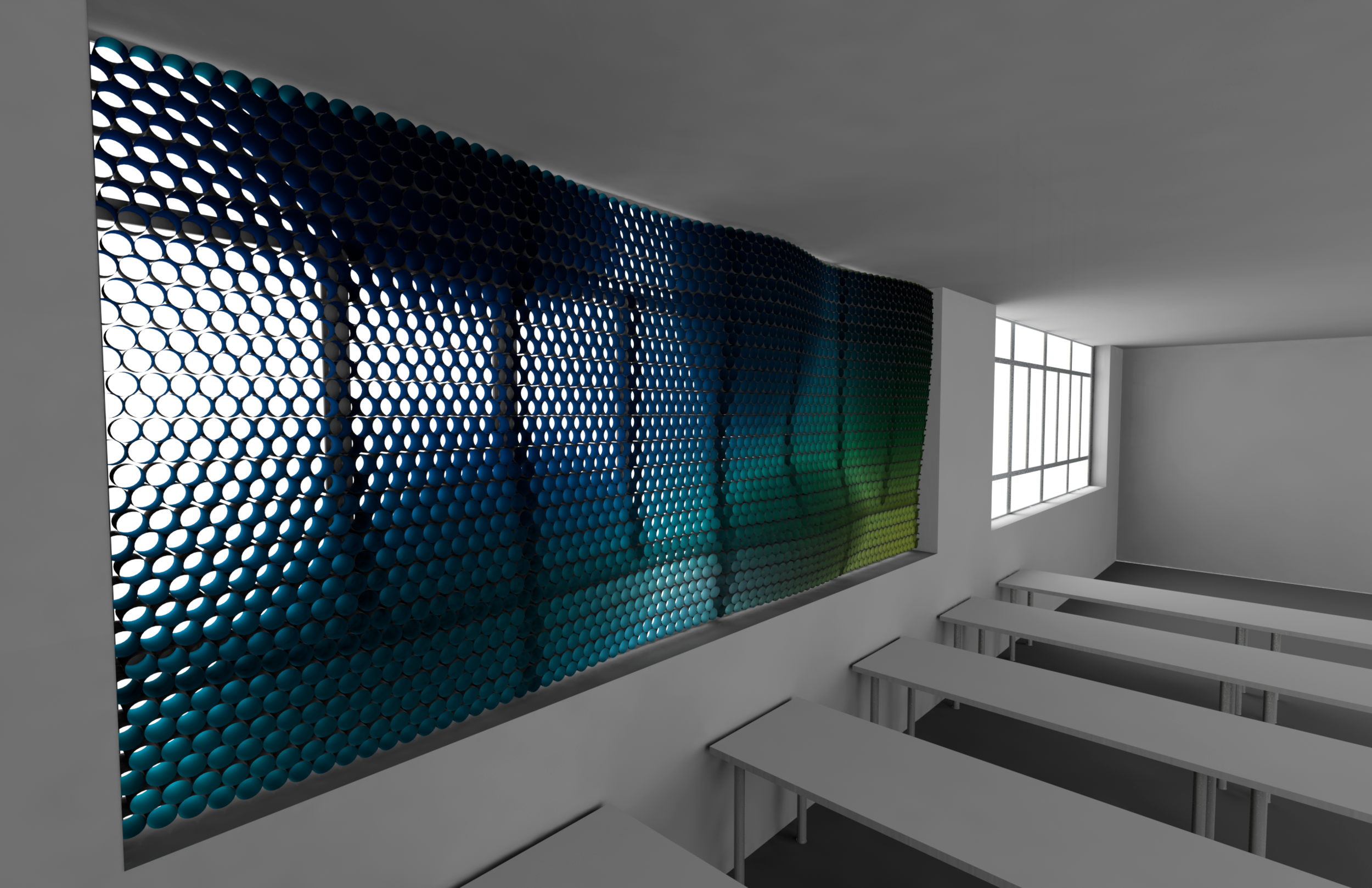

Done in conjunction with 7 other students, Eva Benson, Adrianna Hamzelue, Deanna Molkenbuhr, Stephanie Murri, Henry Nissani, Heather Piña, & Diana Rodriguez, we created a curtain wall to address issues of excess heat & brightness in our design studio. Know for its extreme temperature swings, especially during San Jose's Spring & Fall months while classes were held, we sought to elevate come of these issues while using mainly reclaimed materials.

Using a temperature study calculation, I was able to use basic metrics such as the window square footage, the fact that it is a Northern Facing window, the latitude & longitude of our classroom, the fact that it is a single pane window , etc., to calculate how much heat is gained/lost through this set of windows. This calculation then put the measurement into a unit that can easily be compared with the energy it takes to heat & cool a building, so that we could see what the impacts could be.

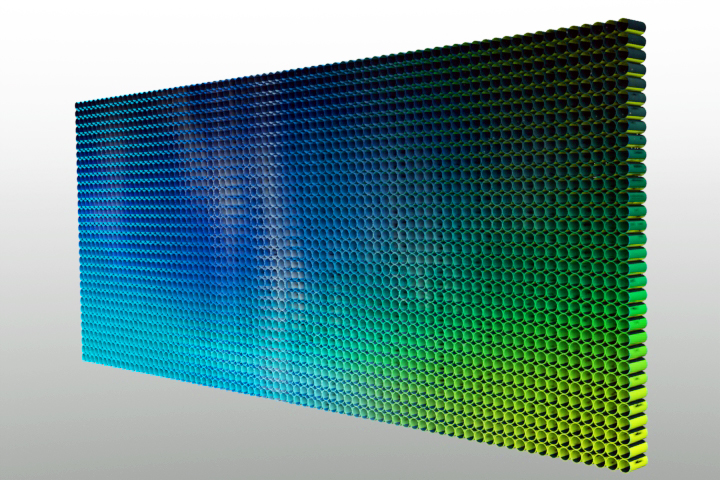

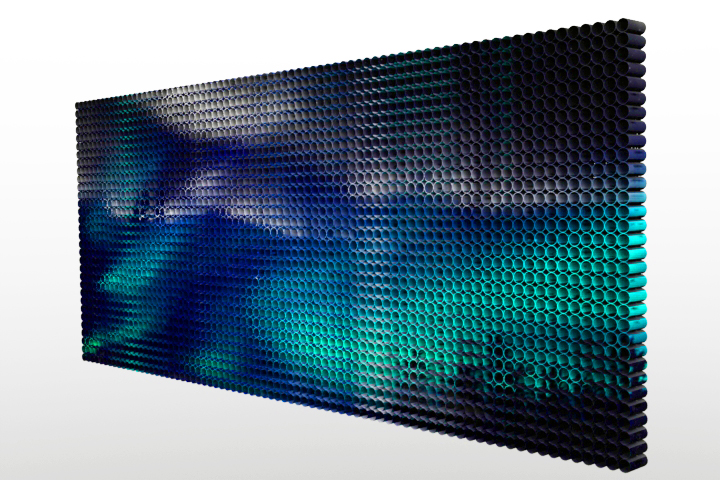

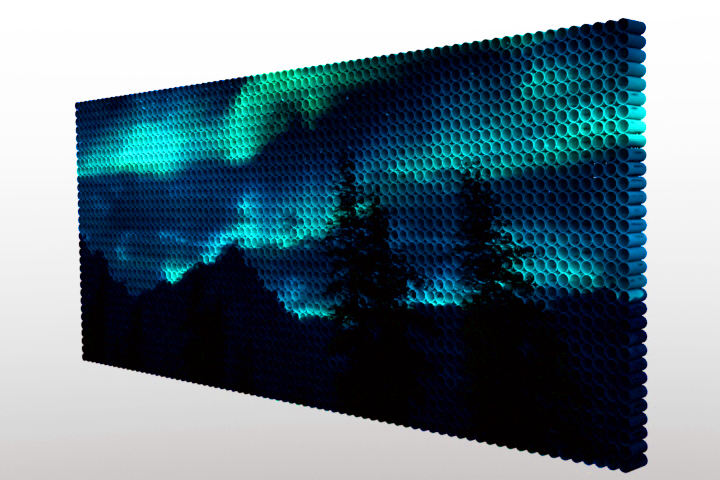

Once we knew what we were working with in terms of the site, we started with materials we found in our materials library in our design studio, & started playing with the various applications & properties that these materials had. After trying many study models, we decided that cylinders would be our best option, using the paint chips for the inner core, with fabric wrapped around the exterior for aesthetic purposes. Once we decided on the form, we needed to decide how to make this into a curtain wall that would cover the entire surface area of our studio window. We used images of the Aurora Borealis as a way to layout the color, & undulated the lengths of the cylinders to create different heat & light gain in different areas of the wall.

Creating a grid of what colors & lengths would go where, we divvied up the workload & brought sections home at night to do, & then continue our work in assembly lines during studio hours.

We then had to install this curtain wall, & decided to use steel cables, & used masonry drills to anchor these into the concrete framing above our windows.

Studio: DSIT 109: Design Build Seminar

Media: SketchUp, Photoshop, Illustrator, Podium, Modo, Recycled Materials, Hand Modeling & Fabrication, Energy Efficiency Skills learned in ENVS 132: Solar Home Design, ENVS 133: Alternative Energy Strategies, & ENVS 137: Green Building Design Issues

Location: SJSU Industrial Studies Building, Interior Design Studio